360° Label Inspection Machine

1.360 degree inspection

2.Muli view stiching and color recogniton technology are more reliable

3.The maximum speed is up to 36000 BPH

I. Project Design Basis

1. Project Overview

1.1 Project Name: PET Bottle Label Online Inspection Machine

1.2 Project Description

Utilizing advanced machine vision inspection technology, this system performs fully automatic, non-contact online inspection of PET bottle labels, including the presence and height of labels.

1.3 Rated Output: 60,000 units/hour.

1.4 Bottle Type: PET bottle.

2. Environmental Conditions

2.1 Optimum Altitude: 5-3000 meters above sea level;

2.2 Optimum Ambient Temperature: 5°C-40°C;

2.3 Optimum Ambient Humidity: 50-65% RH;

2.4 Factory Conditions

Parameters such as floor levelness and load-bearing capacity must meet relevant national standards and satisfy the normal operating requirements of the machine;

2.5 Factory Storage Conditions

After arriving at the factory, parts and machines must be stored in a location that complies with relevant national standards.

3. Equipment Operating Conditions

3.1 Noise: ≤85 dB; actual noise levels may vary depending on the container/package being processed, machine power, and building acoustic characteristics.

3.2 Voltage: 220V, 50Hz, single-phase (special voltages require prior notification).

3.3 Total Power: Approximately 1.0kW; Control Voltage: 24VDC.

3.4 Compressed Air: 0.5MPa, air consumption per rejection cycle approximately 0.01L.

II. Equipment Introduction

1. Installation Location: On the single-row straight conveyor line behind the labeling machine.

2. System Working Process

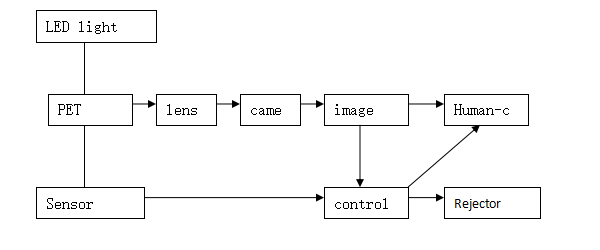

Figure: System working principle and flow chart

3. System Operation

3.1 When a bottle passes the positioning sensor, its presence is detected. The control unit then logs the bottle ID and the current encoder reading.

3.2 The positioning sensor activates the camera to capture an image of the label on the current bottle. Post-acquisition, the image processor analyzes the image and sends the processed results to both the human-machine interface (HMI) for real-time dynamic display and the control unit to facilitate the removal of defective bottles.

3.3 Upon receiving the defect signal, the control unit instructs the rejector to remove the bottle corresponding to the specified ID.

4. Image Acquisition Components

4.1 Light Source: An LED area light source is adopted, boasting a service life of up to 50,000 hours. Foreground lighting is employed to clearly present the details of the measured object. In the captured image, the bottle mouth appears as a continuous bright circular ring. A manual iris fixed-focus lens is used: adjust the focus ring to achieve the sharpest image on the CCD target surface, and fine-tune the iris ring to optimize image brightness.

4.2 Camera: An area scan CCD analog camera is utilized, featuring a resolution of 640 x 480 pixels and an image capture speed of up to 60 frames per second.

5. Inspection Content and Accuracy

5.1 Inspection Content

1).No label

2).High label

3).Low label

4).Positive and negative label (wrong label orientation)

5.2 Detection Accuracy

serial number

| Test Contents | Testing Accuracy | Rejection rate

| False rejection rate

|

1 | No label | --- | 100% | ≤0.03% |

2 | High label | Deviation ≥ 2mm | ≥99.9% | |

3 | Low label | Deviation ≥ 2mm | ≥99.9% | |

4 | Connection label (tape applied when changing labels, requires a significant color difference between the tape and label) | ≥99.9% |

7. Equipment Structure and Components

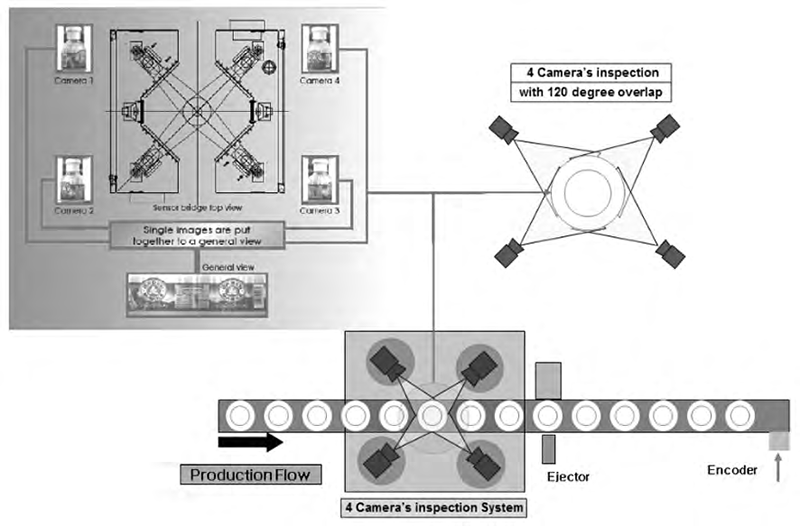

7.1 The machine is composed of multiple detection units and a human-machine interface (HMI), making it suitable for label inspection on high-speed production lines.

7.2 The detection unit adopts a stable industrial control computer for data processing, which interacts with the control unit to transmit inspection information seamlessly.

7.3 The electronic control system integrates imported programmable logic controllers (PLCs), program memory, photoelectric switches, inductive switches and other components. Combined with a comprehensive program control and HMI interface, it forms a sophisticated automatic control system.

7.4 A rejection confirmation unit is configured to guarantee the accurate removal of all defective products.

7.5 The power distribution cabinet is equipped with an industrial air conditioner to maintain an optimal internal temperature, thereby extending the cabinet's service life.

7.6 The compact design of the inspection cabinet effectively reduces the equipment's floor space requirement.

7.7 The machine's operating status and fault conditions are displayed in a graphical format on the HMI for intuitive monitoring.

8. System Advantages

8.1 The hardware of the image processing system adopts industry-leading imported components, while the software incorporates specialized image processing algorithms, enabling high-speed, high-precision and highly reliable inspection operations.

8.2 Customized programs for various bottle types can be pre-installed, supporting one-click bottle type switching for enhanced operational efficiency.

8.3 Equipped with a rejection confirmation unit, it performs real-time online monitoring to ensure defective bottles are correctly rejected, achieving reliable closed-loop control throughout the entire inspection process.

8.4 The system features a modular design with abundant interfaces and expansion space, providing strong scalability for future upgrades.

8.5 The equipment boasts an extremely low failure rate and offers simple, convenient maintenance procedures.