Can Level Detection Technology: The "Invisible Guardian" of Beverage Quality

On the production line, thousands of cans race past at a rate of one minute, while a pair of "eagle eyes" constantly safeguard the quality of our beverages.

In modern bottling plants, cans flow along conveyor belts at a rate of over 1,200 cans per minute. The naked eye can barely discern the details of each can, yet one of the most critical quality indicators—the liquid level—is directly related to product quality and corporate reputation.

Liquid level detection technology solves the industry's difficulty in visually observing the liquid level in sealed containers, becoming an indispensable quality control step in bottling lines for beverages, beer, and other products.

1. Technical Principle: How X-rays "See Through" Cans

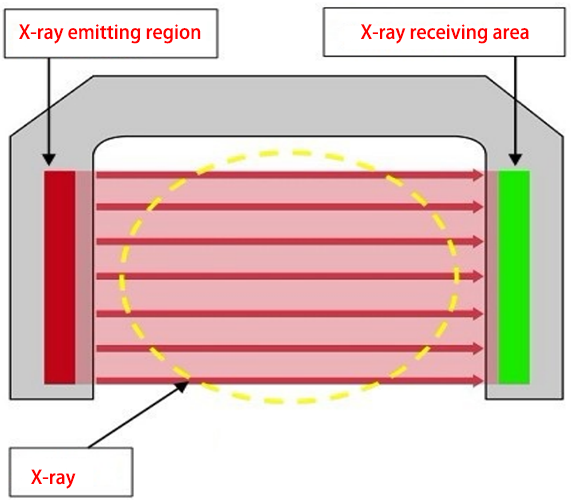

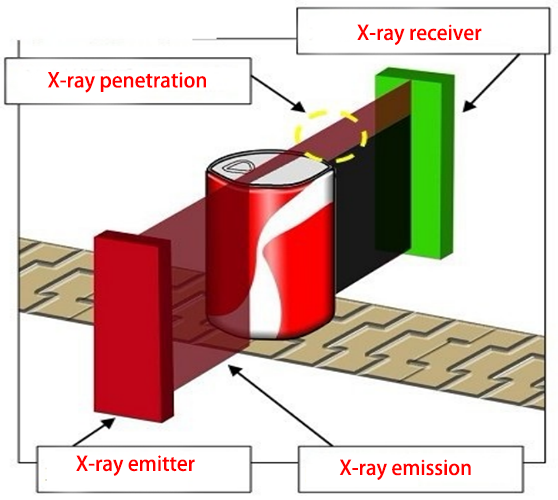

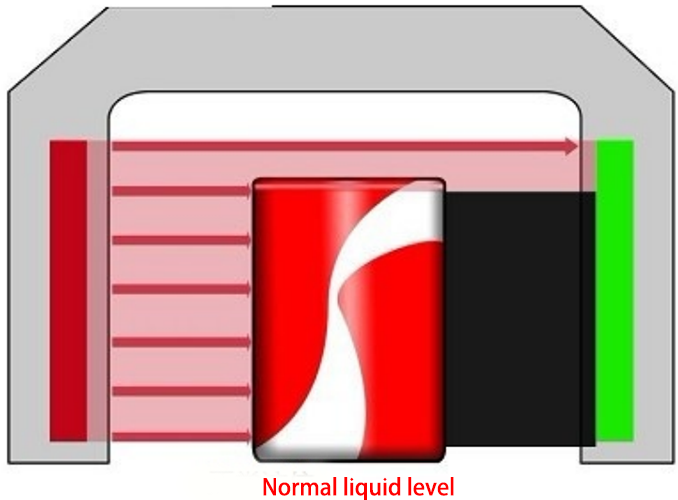

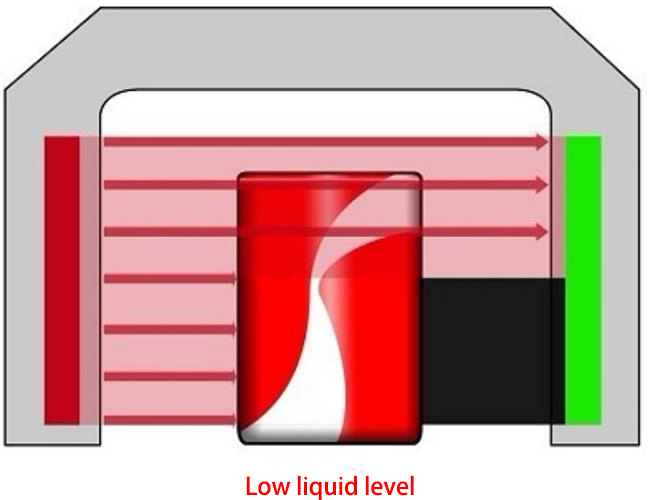

Can level detection technology is based on the physical principles of the interaction between radiation and matter. When X-rays penetrate a can, the liquid inside absorbs and attenuates the radiation. Different liquid levels result in varying radiation intensity at the detector.

By analyzing these intensity variations, the system accurately determines the actual position of the liquid surface in the can. The entire inspection process involves three key steps:

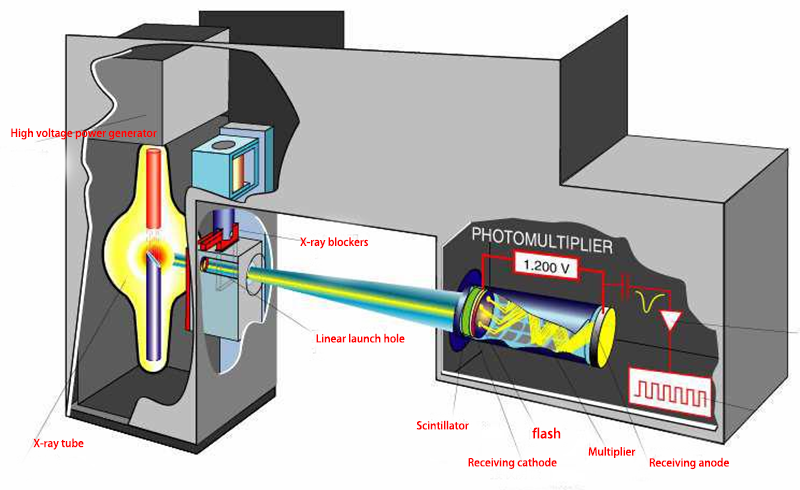

Signal Acquisition: An X-ray source generates a stream of low-energy photons that penetrate the moving cans; a detector receives the transmitted radiation and converts it into an electrical signal.

Signal Conversion: The collected analog signal is converted to a digital signal via a converter such as the AD781 for subsequent processing.

Intelligent Decision: Using an FPGA (field programmable gate array) or embedded system as the core controller, the digital signal is analyzed and processed, compared with preset standard values, and a real-time determination of liquid level compliance is made.

This non-contact measurement method fundamentally solves the problem of conventional weighing methods being unable to measure the volume of liquid materials filled on the production line.

2. Technological Evolution: From Manual Spot Checks to Fully Automated Inspection

Before the advent of liquid level detection equipment, the beverage industry primarily relied on manual spot checks for quality control. Production line workers periodically extracted small amounts of product from the line and estimated the liquid level by weighing or shaking. This method was inefficient, had high errors, and could not achieve comprehensive quality control. With technological advancements, liquid level detection technology has undergone three major evolutions:

Phase 1: Contact-based mechanical detection, which measures liquid levels through physical contact but is prone to product contamination and slow.

Phase 2: Optical and ultrasonic detection technologies, which enable non-contact measurement, but are less adaptable to opaque containers and liquid characteristics (such as color and foam).

Phase 3: The application of X-ray imaging technology, which truly enables fast, accurate, non-contact detection of opaque containers such as cans.

Modern liquid level detection equipment has evolved into intelligent systems that integrate X-ray technology, machine vision, and automatic control, achieving detection accuracies of ±0.5 mm and speeds exceeding 1,200 cans per minute.

3. Technical Advantages: Why It Has Become an Industry Standard

The rapid adoption of can level detection equipment in modern production lines is primarily due to its multiple technical advantages.

High precision and efficiency are its core strengths. Under static conditions, detection accuracy reaches within ±0.5mm, sufficient to meet the most stringent industry standards. The detection speed can match high-speed production lines, with a maximum processing capacity of 72,000 cans per hour, enabling full-line product quality monitoring.

The equipment's strong adaptability enables it to cope with complex production environments. It can handle containers of varying capacities (250ml-1000ml) and shapes, and its strong anti-interference capabilities allow for stable operation in humid and vibrating industrial environments.

Data traceability enhances quality management. The system records each product's inspection data in real time, supporting production batch traceability and quality analysis, providing a basis for process optimization.

Compared to traditional detection methods, automated liquid level detection equipment can significantly reduce operating costs. The non-contact sensor has a long lifespan and is easy to maintain. Furthermore, by precisely controlling the filling volume, it effectively reduces product waste.

4. Application Scenarios: From Production Lines to Brand Protection

The application scope of can level detection equipment has expanded to multiple key areas. In the quality control phase of the filling line, equipment is typically installed after the filling and capping processes. It monitors the liquid level of each can in real time, promptly identifying and rejecting substandard products and preventing them from entering the market.

For production line upgrades and renovations, liquid level detection equipment is a key component that replaces traditional manual spot checks and enhances the intelligence of the production line. It seamlessly integrates with PLCs (Programmable Logic Controllers) or Industrial Internet of Things systems to achieve fully automated control of the entire process.

In new product development, the flexible compatibility of detection equipment enables companies to quickly switch between different can types, meeting new product trial production and launch requirements, significantly shortening the product launch cycle.

Most importantly, by ensuring consistent liquid levels in each can, liquid level detection equipment effectively prevents consumer complaints and safeguards brand image and market reputation.

5. Innovation Trend: Intelligent and Integrated Development

With the advent of Industry 4.0, can liquid level detection technology is evolving towards a more intelligent and integrated approach.

The integration of multiple technologies is a clear trend. X-ray inspection, combined with machine vision and artificial intelligence algorithms, can not only detect liquid levels but also detect defects such as can neck deformation, foreign matter, and inkjet printing quality. Deep data utilization is another development direction. Modern inspection systems are no longer content with simply distinguishing between qualified and unqualified products. Instead, they use real-time analysis of inspection data to provide feedback and parameter adjustments for upstream filling equipment, creating a closed-loop quality control system.

Miniaturization and energy efficiency are also key areas of technological evolution. The new generation of equipment utilizes a safer soft-radiation design and contains no isotope radiation sources. While ensuring safety, it reduces energy consumption to below 150W, in line with the concept of green manufacturing.

Future liquid level inspection systems will gradually evolve into production line quality monitoring centers, integrating multiple inspection functions and providing comprehensive production quality data analysis to support business decision-making.

With continuous technological advancements, future liquid level inspection equipment will become even smaller and more intelligent, potentially even incorporating artificial intelligence and machine learning algorithms to predict potential filling equipment failures, proactively implement maintenance, and eliminate liquid level anomalies at the source.

Quality inspection is no longer just a production step; it has become a data-driven system for continuous optimization. As industry experts have stated, "The value of liquid level inspection equipment lies not only in eliminating unqualified products but also in providing companies with the data foundation for optimizing production processes."