News Center

AbstractWith the accelerated digital transformation and upgrading of the baijiu industry, packaging coding inspection, as a key link in ensuring product quality and anti-counterfeiting traceability, is facing an urgent need to transform from traditional manual inspection to intelligent and…

2026/02/10 11:17

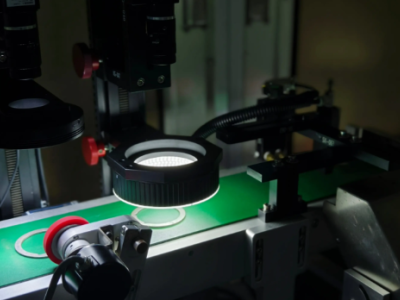

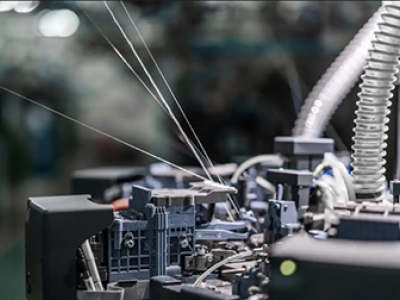

Visual inspection technology utilizes image acquisition equipment and computer algorithms to achieve efficient and precise non-destructive quality monitoring in industrial production. The table below provides a quick overview of its core components and key capabilities.Detection System Core…

2026/02/09 10:38

Using machine vision for defect detection of beverage bottle caps enables efficient and precise control of product quality. The table below summarizes the main detection categories and methods, helping you quickly understand the core content.Detection CategorySpecific Defect TypesCommon Technical…

2026/02/06 11:08

Visual inspection technology, by simulating and surpassing human vision, equips bottle and can production lines with tireless "all-seeing eyes," fundamentally changing the mode and standards of quality control. Through high-precision automated inspection, it not only significantly improves the pass…

2026/02/04 13:29

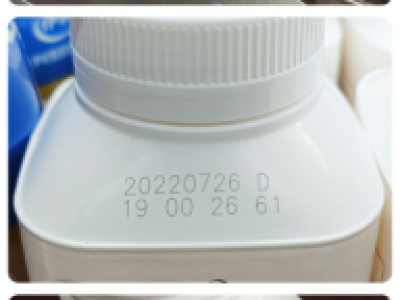

Those seemingly insignificant inkjet codes are actually the first quality control checkpoint for dairy beverages entering the market.On high-speed dairy beverage production lines, hundreds of products pass through filling, packaging, and inkjet coding every minute. The inkjet code, acting as the…

2026/02/03 10:21

Machine vision technology, by simulating human visual functions, provides a more efficient and accurate automated solution for beer bottle quality inspection, fundamentally improving the quality control level of the production line.The table below clearly shows the application of machine vision in…

2026/02/02 11:11

A gamma ray level meter is a specialized instrument that uses the attenuation characteristics of gamma rays to measure the level of a medium in a container. It is primarily used in industries such as petroleum, chemical, pharmaceutical, power, and metallurgy. It calculates the liquid level by…

2026/01/30 10:28

In aseptic filling technology, dry and wet sterilization are two main methods for sterilizing packaging materials (such as bottles), and they differ significantly in principle, efficiency, cost, and environmental impact.Dry SterilizationDry sterilization is an environmentally friendly technology…

2026/01/28 15:00

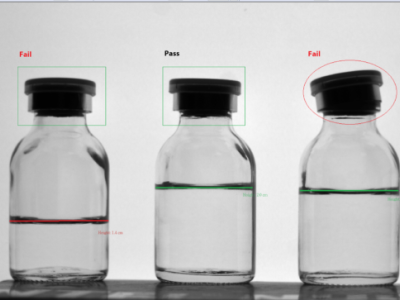

In industries such as beverages and pharmaceuticals, precise liquid level control is crucial for product quality and corporate reputation.Accurate detection of liquid levels in glass bottles has become a critical aspect of modern industrial production. Traditional manual visual inspection methods…

2026/01/27 13:13

The tiny, almost invisible cracks on the packaging bag may be the culprit behind spoiled and leaking seasonings.On supermarket shelves, packaged seasonings are popular with consumers due to their convenience and affordability. However, behind this packaging lies a frequently overlooked quality risk…

2026/01/24 16:17

On high-speed modern production lines, precise quality control is a crucial line of defense for protecting corporate reputation and consumer safety.As the "quality gatekeepers" on the production line, full-box weighing and inkjet code visual inspection technologies, from the dimensions of weight…

2026/01/23 14:09

Detailed Explanation of Tetra Pak Lid Adhesive Quantity Detection Technology: A Key Aspect in Ensuring Packaging SealingThose seemingly insignificant traces of glue are actually a crucial line of defense in ensuring the safety and quality of dairy products.In the field of liquid food packaging, the…

2026/01/21 15:32