News Center

In the food and beverage industry, a small piece of transparent film, a metal fragment, or a glass shard can pose a significant threat to product quality. Foreign object detection after filling and before sealing cans is a critical line of defense in ensuring food safety.In the can production…

2025/12/15 15:59

Behind those seemingly simple aluminum cans lies precise quality inspection technology.On modern food and beverage production lines, hundreds or even thousands of aluminum cans flow through at high speed every minute. Ensuring that the liquid level in each can meets standards is a huge challenge.…

2025/12/12 08:49

Food bags whiz by on the production line at a rate of 300 per minute, while an advanced vision-based inspection system captures every printing defect with 100% accuracy, minimizing food safety risks.On high-speed food production lines, the production date, expiration date, and batch number on each…

2025/12/11 07:49

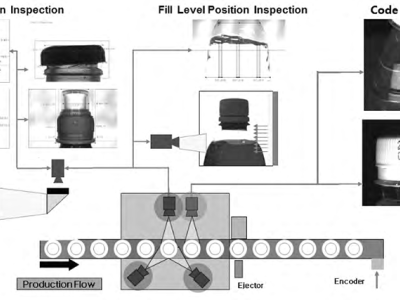

On modern filling production lines in industries such as beverages, daily chemicals, and pharmaceuticals, every bottle must undergo a crucial "visual inspection"—liquid level visual inspection—before capping. This technology acts like a tireless "smart eye" on the production line, accurately and…

2025/12/10 13:47

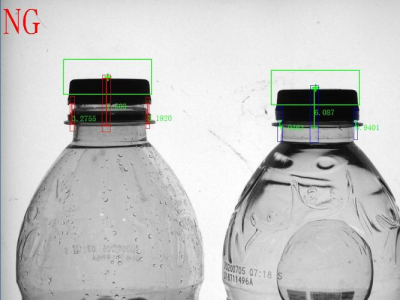

1. Importance and Background of Full-Bottle Inspection for PET BottlesPET bottles are widely used packaging containers in the beverage, food, and pharmaceutical industries. On high-speed filling production lines, defects such as excessively high or low liquid levels, and substandard cap sealing may…

2025/12/09 16:46

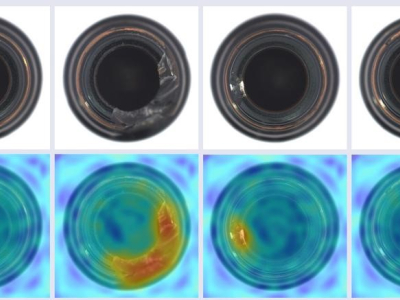

In the food, pharmaceutical, and cosmetic industries, glass bottles are widely used as packaging materials due to their high chemical stability and excellent barrier properties. However, during production or filling, foreign objects such as metal fragments, glass shards, hair, or fibers may become…

2025/12/08 10:58

Foreign object detection in bottled beverages is a crucial step in food safety production. Currently, mainstream detection technologies have achieved a high degree of automation, efficiently identifying and rejecting substandard products. Below are some core detection methods.Image Sequence-Based…

2025/12/05 10:02

On high-speed intelligent production lines, a system safeguards the "identity information" of every product at millisecond speeds.In modern industrial production, the markings on product packaging—production date, shelf life, batch number, QR code, etc.—are not only the product's legal identity…

2025/12/04 14:17

A food X-ray machine is a key quality control device on modern food production lines. Utilizing the penetrating properties of X-rays, it efficiently and accurately detects various foreign objects and product defects in food, becoming an important tool for ensuring food safety.Working Principle and…

2025/12/03 10:55

Detecting leaks in aluminum-bottom tinplate cans requires selecting the appropriate method based on the production process and precision requirements. Below is a summary of common detection methods, their applicable scenarios, and some practical operational points.Overview of Common Leak Detection…

2025/12/02 12:00

On a modern production line, as parts pass through an inspection system at speeds of several meters per second, minute defects imperceptible to the human eye are identified and sorted in real time. Behind this seemingly simple process lies the deep integration of optical imaging, artificial…

2025/12/01 10:50

Introduction With the rapid development of artificial intelligence and automation technologies, machine vision inspection, as an efficient and accurate inspection method, is playing an increasingly important role in fields such as industrial manufacturing, medical diagnosis, and security monitoring…

2025/11/20 11:46