Can Liquid Level Detection and Filling Management: Quality Assurance Through Precise Control

On high-speed filling production lines, cans of beverages are undergoing precise testing regarding their volume.

In the industrialized production of beverages, liquid level accuracy is one of the key indicators of product quality. Overfilling leads to product waste and increased costs, while underfilling can trigger consumer complaints and damage brand reputation.

Statistics show that the cost losses caused by substandard liquid levels can account for 2%-5% of total production costs. Modern can liquid level detection technology, through high-precision and automated methods, improves liquid level control accuracy to within ±0.5mm, becoming a core link in ensuring filling quality.

1. The Importance of Liquid Level Detection: A Multidimensional Balance of Quality, Cost, and Brand

Liquid level detection plays multiple roles in can filling. From a quality perspective, substandard liquid levels may indicate sealing problems, leading to beverage spoilage or carbon dioxide leakage.

For carbonated beverages, overfilling can lead to excessive pressure inside the can, potentially causing bottle bursts in severe cases. Underfilling directly harms consumer interests and affects brand reputation.

Economically, precise liquid level control means direct cost savings. Taking a production line with an annual output of tens of millions of cans as an example, reducing overfilling by 1ml per can can save tens of thousands of liters of raw materials annually.

Liquid level detection equipment can identify and remove substandard products in real time during high-speed operation, preventing large-scale defective products from entering the market.

Modern filling management systems not only detect liquid levels but also collect important information about overall product quality and monitor the performance status of filling and capping machines. They provide accurate statistical data on each filling valve, providing early warnings before defective filling valves completely fail, avoiding production interruptions and batch losses.

2. Analysis of Detection Technology: The Evolution from Traditional to Advanced Methodologies

With technological advancements, can liquid level detection technology has evolved from simple to complex, from contact-based to non-contact methods. Currently, the mainstream detection technologies mainly include optical, ultrasonic, and X-ray technologies.

X-ray detection technology is currently the most widely used high-precision detection solution. Its working principle is based on the fact that when X-rays penetrate the container, different liquid levels create different projections at the X-ray receiver. The system determines whether the liquid level is acceptable by analyzing the numerical changes in these projections.

This technology offers high precision, reaching ±0.4mm, and a detection speed of over 1500 cans per minute.

Optical detection technology uses a camera to capture the liquid level position and is suitable for transparent or translucent containers; ultrasonic technology determines the liquid level height based on echo time and is suitable for various types of containers. The advantage of optical technology is its speed, but it is limited by the transparency of the container; ultrasonic technology is not affected by the container material, but may be susceptible to environmental interference.

Modern advanced detection systems such as MAOTONG employ a modular architecture, integrating multiple detection programs. They can not only perform liquid level detection but also conduct 360-degree inspection of the entire container closure, identifying problems such as bent or tilted caps and damaged sealing rings.

Some systems also integrate the MAOTONG O2 module to detect residual air that can cause rapid product spoilage.

3. Filling Management System: The Integration of Automation and Intelligence

Modern filling management systems are far more than simple liquid level detection; they are complex systems integrating sensing technology, PLC control, and data traceability. The system uses a PLC (Programmable Logic Controller) as its core, monitoring production status in real-time through high-precision sensors, forming a closed-loop control system.

During system operation, the PLC acts as the "nerve center," relying on feedback data from sensors at each stage. Photoelectric sensors detect the position and quantity of empty bottles; weighing sensors monitor weight changes during the filling process; and liquid level sensors detect the liquid level in the container. These sensors convert physical signals into electrical signals, providing the basis for the PLC's decisions.

Filling control is the core function of the system. Modern systems employ a closed-loop control strategy, using weighing sensors and liquid level sensors as feedback elements, combined with PID control algorithms to build a filling volume adjustment system.

For different types of beverages, the system can set multiple filling modes. For example, for carbonated beverages, isobaric filling technology is used, controlling the pressure balance between the filling head and the bottle to reduce bubble formation.

The filling management system also has powerful data traceability capabilities. The system collects data such as yield, filling pass rate, and equipment operating time in real-time, uploading it to a database via industrial Ethernet such as PROFINET. This data can be used not only for real-time monitoring but also to generate production trend analyses, helping to identify bottlenecks and quality fluctuations in the production process, providing a basis for continuous optimization.

4. Technical Parameters and Performance Comparison of Liquid Level Detection Equipment

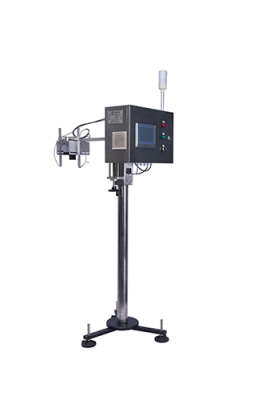

There are various types of beverage can liquid level detection equipment on the market, each with different performance parameters to meet different production needs. The more advanced MT-HFX-06H model can even achieve a detection speed of 2000 cans per minute, or up to 120,000 cans per hour.

These devices typically use 304 stainless steel and are suitable for environments with temperatures of 0-50℃ and humidity of 0-90% (non-condensing). They are installed on a single, straight, non-pressurized line after filling, capping, and warming. The equipment weighs approximately 80kg, has a power of 100W, and supports AC220V/110V voltage.

Advanced liquid level detection equipment also integrates filling management functions, including a traceability system and filling head detection capabilities. These functions enable the system to identify the source of faults leading to repeated incorrect filling, detecting and correcting problems at an early stage to prevent high rejection rates and prolonged production downtime.

Comparing the application scenarios of different technologies, X-ray technology offers high precision and speed, suitable for high-speed, large-scale production lines; optical technology is less expensive and suitable for scenarios where extreme precision is not required; and ultrasonic technology performs exceptionally well with certain container materials. Companies should choose the appropriate detection solution based on their product characteristics, production speed, and precision requirements.

5. Operating Procedures and Safety Management: Ensuring Detection Reliability

Correct operating procedures are essential for ensuring the reliable operation of liquid level detection equipment. Before operation, a device check must be performed to ensure that the equipment is functioning correctly and to check for any abnormal phenomena such as unusual noises.

Operators must wear appropriate personal protective equipment, such as work clothes, safety helmets, and gloves, to ensure personal hygiene.

The operation of the filling equipment should strictly follow the equipment's operating manual. Personnel who are untrained or unfamiliar with the equipment should not operate it. During the filling process, the liquid level should be checked frequently to ensure that the liquid level of light and heavy beverages is not below the set value.

In terms of safety measures, relevant safety precautions must be taken when using filling equipment, such as setting up warning signs and providing fire extinguishers. Smoking, drinking, and horseplay are prohibited in the workplace to ensure safety. In emergency situations, operators must know how to quickly shut down or disconnect the power.

Regular maintenance is crucial for ensuring the long-term stable operation of the equipment. This includes keeping the equipment dry, performing regular inspections and maintenance, and cleaning all components inside the filling machine. The air-water separator's filter and water collection cup and filter element need to be cleaned regularly to ensure the equipment is in optimal condition.

6. Innovative Technologies and Future Trends: Intelligent and Adaptive Control

Can liquid level detection technology is developing towards a more intelligent and adaptive direction. An automatic can filling control system based on an embedded microcontroller uses the STM32MP151 microcontroller as the control core, with an external touch screen for control, and position sensors and photoelectric sensors to achieve automatic identification and detection throughout the entire process.

The robotic arm's grasping path uses a fuzzy control method, creating a fuzzy PID controller with error e and error rate ec as inputs, achieving precise control through quantization functions and fuzzy rule tables.

Another innovation is the star wheel transmission filling system, which integrates the gas displacement mechanism and the capping machine, allowing the lid and can body to move synchronously before assembly. During this process, the can body undergoes carbon dioxide displacement until capping is complete, effectively preventing oxygen from entering and ensuring product quality.

This design shortens the travel of the filling system, reduces the footprint, and avoids liquid splashing caused by impact forces on the cans.

In the future, with the development of the Internet of Things and artificial intelligence technologies, liquid level detection systems will become more intelligent. Data transmission based on 5G networks can enable equipment fault prediction, and big data analysis can optimize filling parameters.

Adaptive control algorithms can automatically adjust filling parameters based on beverage characteristics, improving the system's adaptability to different products.

With technological advancements, the accuracy of can liquid level detection has progressed from millimeters to micrometers. New detection equipment such as the MT-HFX-06H can reach speeds of up to 1500 cans per minute with an accuracy of ±0.4mm, while costs are decreasing year by year. This progress allows small and medium-sized enterprises to also benefit from the quality advantages brought by high-precision detection.

In the future, liquid level detection systems integrated with the Internet of Things and artificial intelligence will become standard configurations. The system will be able to analyze data in real time, predict equipment failures, and adaptively adjust filling parameters, ultimately achieving a shift from "detection" to "prevention." For beverage manufacturers, investing in advanced liquid level detection and filling management systems is no longer just a matter of quality control, but a strategic choice to enhance overall competitiveness.