Bottles Cap Inspection Machine

1.Using self-developed hardware detection system, the fastest processing speed ,is up to 50000 BPH

2.The automatic elimination device is adopted to eliminate the bottle which is dificult to be poured

3.Using a high life LEDlight source, energy saving, environmental protection

I. Equipment Parameters and Site Description

1. Project Overview

1.1 Project Name: Glass Bottle Liquid Level Online Inspection System

1.2 Project Summary:

This system utilizes state-of-the-art machine vision technology to perform fully automated, non-contact inspection of liquid levels in glass bottles, ensuring precise identification and rejection of nonconforming products.

1.3 Rated Capacity: 1000 bottles/min (standard configuration)

1.4 Applicable Bottle Type: Glass bottles

1.5 Product Volume Range: 100 mL – 1000 mL

2. Environmental Requirements

Installation Altitude: 5 – 3000 m above sea level

Operating Temperature: 5°C – 40°C

Relative Humidity: 50% – 65% RH

Factory Conditions: Floor flatness, structural load capacity, and other parameters must conform to national standards to guarantee stable equipment performance.

Storage Conditions: After delivery, all components and the complete unit should be stored in compliance with national standards. During storage, proper lubrication and preventive maintenance must be carried out to avoid surface damage, corrosion, or deformation that could impact installation, commissioning, or long-term reliability.

3. Operating Conditions

Noise Emission: ≤85 dB (actual values vary depending on packaging material, power demand, and site acoustics).

Electrical Supply:

Main Power: 3 × 380V AC ±10%, 50 Hz, 3PH + N + PE

Lighting Power: 220V AC, 50 Hz, single-phase

Note: Special voltage requirements must be confirmed in advance, as they may influence specifications, lead times, and pricing.

Total Power Consumption: Approx. 1.0 kW

Control Voltage: 24 VDC

4. Equipment Description

4.1 Glass Bottle Liquid Level Inspection Unit

Model: MT-RB-CYW-02

Quantity: 1 set

Production Speed: 1000 bottles/minute

Applicable Containers: Glass bottles

Compatible Lines: Glass bottle filling and packaging lines with capacities up to 1000 bottles/minute

Installation Location: Positioned on a single-lane conveyor immediately downstream of the filler (liquid stratification required).

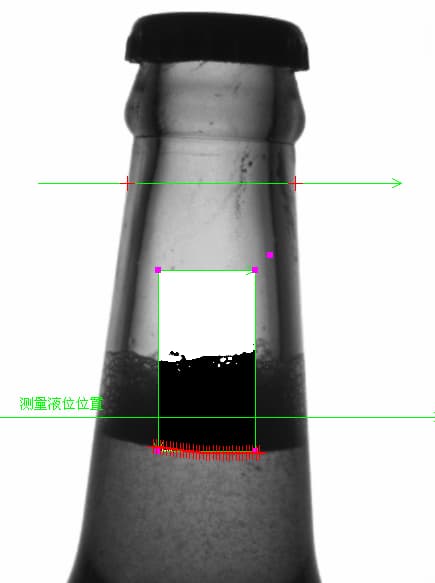

Functionality: A high-resolution workstation camera captures real-time images of each bottle. The system analyzes the liquid level and automatically rejects bottles that fall outside the defined quality specifications.

4.2 System working principle, process and installation location

System Configuration Overview:

Station Function: The camera in Station 1 is responsible for detecting the liquid level of glass bottles.

Individual Module Detection Description:

1. When a bottle passes the positioning sensor, it detects its arrival and the control unit records the bottle ID and the current encoder value.

2. The positioning sensor notifies the camera in Station 1 to capture an image of the current liquid level of the glass bottle. After capturing the image, the image processor processes the image and transmits the result to the human-machine interface for dynamic display. The final result is then transmitted to the control unit, which uses calculations to control the rejection of unqualified bottles (with unqualified liquid levels).

3. Upon receiving the unqualified signal, the PLC notifies the rejector to reject the bottle with the corresponding ID.

4.3 Detection Module:

4.3.1 Detection Content and Accuracy:

Test items | Detection content

| Detection accuracy

| Rejection rate

| False rejection rate

|

Liquid level test |

| ±2mm | ≥99.9% | ≤0.05% |